A petrochemical plant installed Sensoteq Kappa X wireless sensors on crucial pumps that required continuous monitoring due to their history of failures. Vibration analysts meticulously analysed the data and identified early warning signs of potential issues. By implementing this essential proactive maintenance strategy, the analysts calculated that the plant avoided an estimated cost of £30,000.

Machinery and Operations

The petrochemical plant processes chemicals derived from petroleum to develop fibres, solvents and thousands of other products. This operation requires a system of acid circulation pumps and critical seal flush pumps to process the chemicals.

Implementation

Kappa X sensors were installed on the motors of 4kW gear pumps running at 1480 RPM. The sensor transmits short-term tri-axial vibration and temperature readings every 3 minutes. Additionally, spectrum and waveform data readings are sent every 24 hours, up to a range of 10kHz, offering substantial vibration information to detect machinery issues. Although a new pump was installed just one month before the wireless kit, historical shaft problems necessitated closer monitoring of these pumps. Therefore, Kappa X sensors were deployed on pumps and compressors throughout the site to monitor potential machine fatigue and faults.

The Problem

The vibration data for sensors on two separate pumps was collected and analysed with increasing PK-PK levels on pump one. The trend increased throughout the month and the levels rose to between 10-15G’s PK-PK. Whilst this vibration only exceeded the warning alarm, rather than the critical, its problems are evident when compared with the second pump. Pump two maintained a consistent trend across the month at 2G’s PK-PK, highlighting the stark contrast in vibration trends between the two pumps.

The significant difference in vibration levels between the two pumps led to a deeper analysis, where gearmesh harmonics were identified, indicating poor gearmesh in pump one. This condition often arises from misalignment, wear, or damage to the gear teeth, resulting in irregular and increased vibration levels. A running speed of 1480 RPM is displayed as a frequency equaling 296Hz. This directly corresponds to the location of each peak, indicating poor gearmesh on each cycle.

The Time Waveform analysis shown below revealed consistently high G’s PK-PK with modulation occurring at 1xRPM. This pattern indicated periodic vibration issues linked to the rotational speed of the pump.

Additionally, the Circular plot provided a visual representation of the modulation, showing peaks at several specific locations around the circle. These peaks pinpointed the exact areas where the modulation was most pronounced, offering valuable insights into the nature and source of the vibration issues.

The acceleration waterfall plot shows increasing gearmesh vibration between November and December. The sideband peaking on either side indicates the repercussive effects of the gearmesh issue. Following the data analysis, the recommendation was that the machine be pulled for inspection in a planned outage.

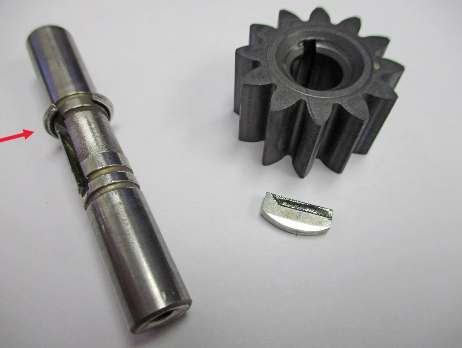

Further investigation revealed that the poor gearmesh in pump one was caused by an incorrect fitment of the circlip on the idler gear. This improper installation led to significant wear on the gear key, evident upon inspection and resulting from looseness. By identifying the root cause through detailed vibration analysis and inspection, the maintenance team addressed the underlying issues stemming from the OEM assembly errors.

The Solution and Result

Following the pump replacement, the sensor recorded a drastic reduction in vibration levels to 3 G’s PK-PK. The correct fitment on the idler gear in the new pump ensured proper alignment and secure positioning of the gears, eliminating looseness and associated wear that caused excessive vibrations. As a result, the new pump shows clean gearmesh.

This outcome not only confirmed the necessity for the pump replacement but also validated the effectiveness of the Kappa X sensors. The plant's ability to detect and address the root cause of the vibration issues underscores the value of implementing advanced monitoring systems to ensure optimal equipment performance and longevity.

Thanks to the Sensoteq Analytix platform, the actionable steps needed to resolve the issues were clearly identified. Maintenance on the machine involved replacing the pump parts and required two hours of labour, totalling £1,427. Without the early detection and precise insights provided by the Sensoteq Kappa X sensors, the plant would have faced a more considerable and expensive repair. Specifically, replacing a new seal pump and acid pump bowl unit, along with the labour for installation, would have amounted to £31,427. The plant avoided these substantial costs by taking timely action based on the detailed vibration data. This significant cost avoidance not only underscores the financial benefits of predictive maintenance but also highlights the value of investing in reliable and sophisticated monitoring technologies.

Enhance your maintenance strategy with Sensoteq and learn more about how our technology can benefit your operations. Contact us today.

Case study supplied by our partner https://rms-reliability.com/